It’s not only about what our tools are made of — it’s about what our people are made of

Getting the right tool is great. Knowing the dedication of the people behind it is even greater. At Active Tooling, we provide much more than tools. We provide long-term service and dedicated relationships. We know many of our customers by name and are personally invested in their success.

Need something delivered? We’ll bring it ourselves. Need something sharpened? We’ll come pick it up. You’ve already got a job to do. We believe packing and shipping shouldn’t be one of them. This mission of outstanding service goes the extra mile – literally. Our team will drive to most parts of Michigan, Ohio, Illinois, and Indiana.

Precision pays off

Active Tooling has decades of combined experience ensuring our customers receive PRECISELY what they need. When tolerances are tight and you need tools manufactured within specs, we guarantee you can rely on us to provide the correct tool for the job. From design to completion, we can provide your custom tool in much less time than our competitors, saving you valuable time to complete your projects. Our precision CNC grinding and inspection machines ensure precision tooling the first time!

See our Renewal Process!

Inspection Process

Our comprehensive inspection protocol commences the moment your blades reach our facility, ensuring every single blade is accounted for and ready for evaluation. Before cleaning our experienced team visually inspects your blades. Blades are then cleaned in our ultrasonic cleaning bath which eliminates any dirt, grit, or pitch build-up.

After cleaning, your blades undergo a thorough inspection by our team to ensure there are no missing teeth, cracks, or other defects which could cause damage to the machine. Then, our state-of-the-art CNC machines precisely sharpen your blade to the exact specifications required with premium diamond-coated grinding wheels. When removed from the machine, your blades are inspected a third time by our team, and then hot dipped in peel coating protections and packaged so that they arrive safely at your door.

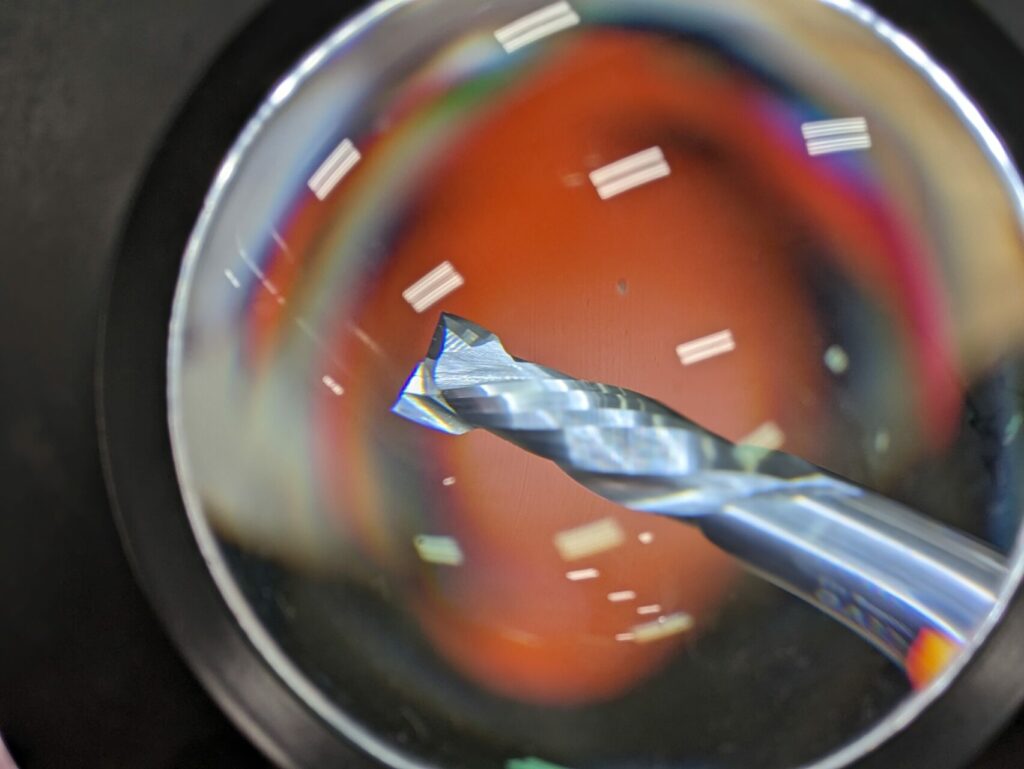

Upon the receival of your solid spiral carbide router bits our team visually inspects the bits for any chips before they are cleaned in our ultrasonic cleaner to remove dirt and grit. Once the cleaning is complete your bits are inspected once again before being sharpened.

Our CNC equipment precisely sharpens the bit’s end, flutes, and outer diameter with a premium diamond-coated grinding wheel. This process guarantees a uniform, high-quality sharpening, which significantly enhances the drill bit’s performance and extending its life. Once this process is complete your bits are hot dipped in peel coating for protection and safely packaged for delivered.

Sharpening

In any manufacturing facility, accuracy isn’t an option, it is a must. When worn, only one blade or bit can compromise the productivity of an entire operation. That’s why we offer tool sharpening services – to keep your tools working to their potential, day in and day out. Our high precision CNC machines don’t just sharpen your tools but bring them back to their peak performance and operating like new again.

What do we sharpen?

Saw blades

Cutters

Router Bits

Knives

Spiral Flute Tools

Drills

Boring Bits

Insert Tooling

How do we do it? If you are within driving distance, we’ll come to your facility, pick up the tools that need maintenance, and sharpen them to your exact specifications. Then, we’ll get them back in a timely, efficient manner. Further away? No problem, just ship them to us and we’ll handle the rest!

Design

Your unique projects deserve one-on-one attention to make sure every angle is covered, and the appropriate tool is selected. We have decades of experience in manufacturing custom tooling to fit any need. Our knowledgeable staff will supply a quote based on the information you supply along with a CAD drawing of the custom tool we’ve designed. Best yet – you don’t pay a dime for this service! Even if you decide not to approve the custom tool, we won’t charge you. Don’t know exactly what type of tool is right for you? No problem. We are here to help! Contact us toll free at 888-766-7437 or email us sales@activetooling.com

Tool Management

Why spend your valuable resources and man hours maintaining and tracking your tooling when Active Tooling will do this for you for no charge!? No matter how small or large your tool room is, we can help! Our tool management program includes weekly pick-ups and returns for local customers free of charge!

We can make sure you are always equipped with the right tool and provide strategic recommendations for service and inventory management that best fits your company’s demands. This means you won’t have to worry your inventory is getting too low, or that blade you set aside may need to be replaced – we have it handled. We are committed to an honest partnership to help you save money and increase that bottom line. Please contact us with questions or direct them to your designated salesman.

How do we do it? If you are within driving distance, we’ll come to your facility, pick up the tools that need maintenance, and sharpen them to your exact specifications. Then, we’ll get them back in a timely, efficient manner. Further away? No problem, just ship them to us and we’ll handle the rest!

Finished with your old solid carbide bits or saw blades?

No problem! Send them to us and we will scrap out your saw blades for you at no charge or provide an account credit for any of your solid carbide tooling!

Coating

At Active Tooling, we’re committed to providing the highest quality, most innovative and cost-effective tooling for the woodworking, solid surface, composite, and metal industry. One way we do this is by offering our Active Advantage Coating to all our solid carbide spiral tools. This gives your tools advantage upon advantage. With our coatings, you’ll get up to 10x the tool life! You’ll also get longer run cycles and less change over time—all at a price that’s less expensive than diamond tooling.

Benefits of Active Advantage Coating

4-8 Times the Tool Life

Longer Run Cycles

Fights Wear Lines

Less Chang Over Time

Combats Heat Build Up

Ejects the Chips More Efficiently

Less Expensive/Cheaper Than Diamond Tooling

No Change to the Diameter of the Tool from the Coating